【24-Hour Free Consultation & Quote】

WeChat/WhatsApp: +86 199 1475 4015

Submit your inquiry and a dedicated engineer will contact you immediately.

{{ variable.name }}

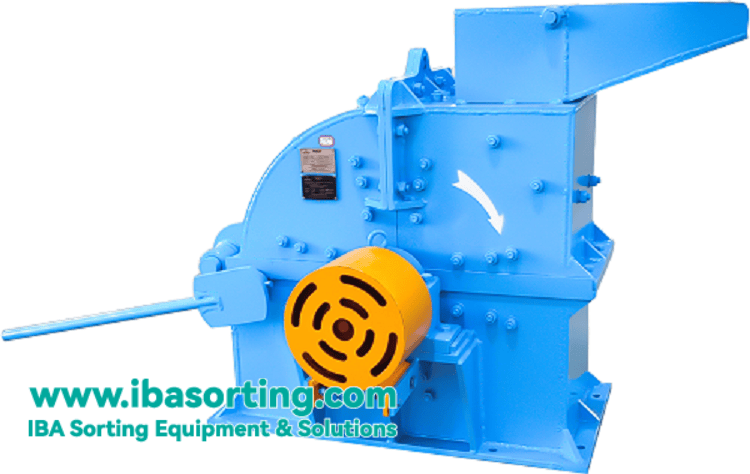

The Slag Crusher Series is a heavy-duty equipment designed for solid waste (especially slag and metal materials) crushing and processing. The series includes Hammer Crusher, Iron Beater (Metal Specialized Crusher) and Twin Shaft Crusher, which can process all kinds of materials from 0-200mm and adjust the discharge size according to the needs. After technical innovation, the equipment effectively solves the problems of noise, water leakage, odor and clogging that exist in the traditional crushing equipment, which is the ideal choice in the field of resource recycling and solid waste treatment.

| Features | Detailed description |

|---|---|

| ✅ Sturdy and wear-resistant, easy to install | Adopting new technology casting hammer head, wear-resistant and impact-resistant. The hammer head is easy to install, and when it is damaged and replaced, you only need to open the cover, so the maintenance workload is less. |

| ✅ Sealed structure, safety and environmental protection | Adopting sealed structure, once feeding crushing molding, with large output, high efficiency, high power, energy saving and environmental protection. |

| ✅ Self-adjustment of discharging granularity | Users can independently adjust the discharge size (coarse, medium and fine) according to the demand, the finished product size is uniform, saving crushing costs. |

| ✅ One-piece casting, solid and durable | Abandon the traditional segmented splicing, the use of one-piece casting process, movable gate molding, beautiful and durable, easy to disassemble. |

| Model | Specification | Application | Capacity | Power |

|---|---|---|---|---|

| PS800 | 800mm×900mm | Large material crushing | 30T/H | 45KW |

| PS800 | 800mm×900mm | Slag crushing | 120T/H | 75KW |

| PS800 | 800mm×900mm | Breaking metal | 30T/H | 55KW |

| PS1000 | 1000mm×900mm | Breaking tailing slag | 60T/H | 90KW |

| PS1000 | 1000mm×900mm | Breaking iron block | 30T/H | 90KW |

| Features | Detailed description |

|---|---|

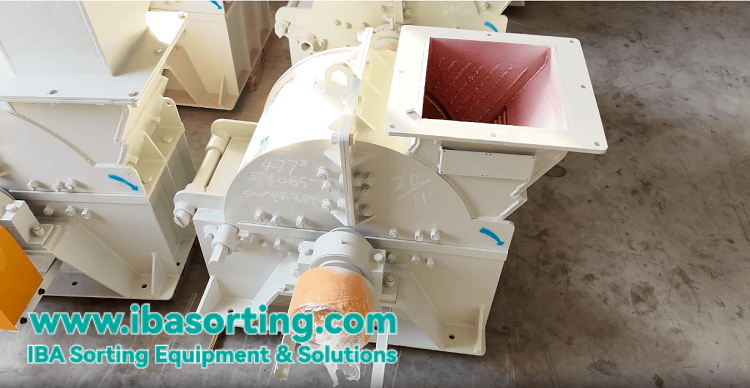

| ✅ Specialized metal crushing | Specially designed for crushing scrap metal, it can handle 0-200mm metal materials with good crushing effect and strong processing capacity. |

| ✅ Sealed environmental protection design | Optimized sealing structure, effective control of noise and odor, in line with the requirements of environmentally friendly production. |

| ✅ Flexible and adjustable discharge | Users can adjust the discharge size according to the demand, to meet the requirements of different subsequent processing technology. |

| ✅ One-piece structure | Adopting one-piece casting, solid structure, easy maintenance and long service life. |

| Parameter | Indicator of the |

|---|---|

| Specification size | 2820×1970×1500(mm) |

| Working voltage | 380V/50Hz |

| Working ambient temperature | -20℃~+40℃ |

| Equipment power | 90KW |

| Processing capacity | 50-80T/H |

| Equipment weight | 6500KG |

| Noise value | 65-70db |

| Features | Detailed description |

|---|---|

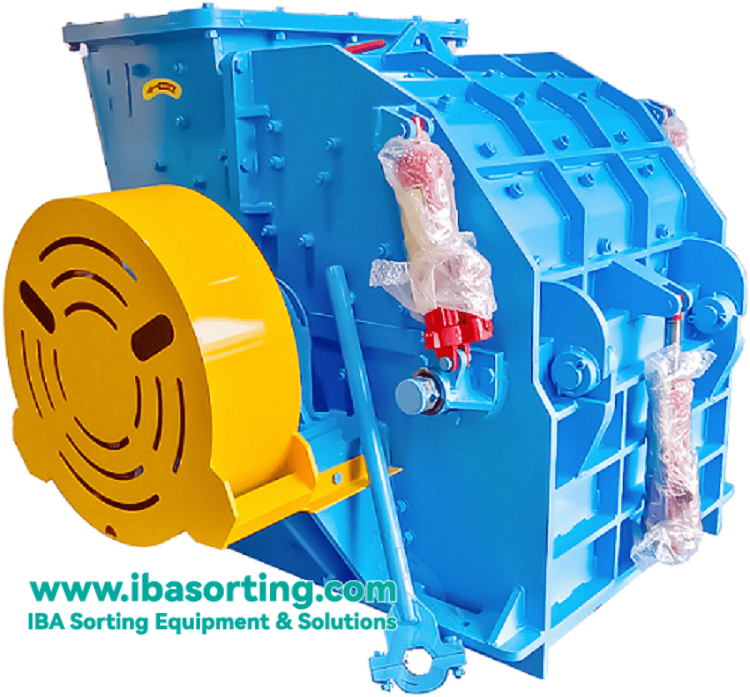

| ✅ High efficiency shear crushing | Adopting the working principle of mutual shearing, tearing and squeezing of double shafts, low rotational speed, high torque, good crushing effect and strong adaptability. |

| ✅ Innovative three-box structure | Upper and lower toothed knife crushing in the box, improving output and reliability, adapting to viscous, high humidity and dirty materials. |

| ✅ Environmental protection and stable operation | Solve the problems of exhaust gas, clogging, easy to break down, stable and reliable operation, easy maintenance, long service life. |

| ✅ Fine granularity | The granularity of crushed products can reach 20mm, which can meet the requirements of fine crushing. |

| Parameter | Parameter |

|---|---|

| Specification size | 2500×2500×1320(mm) |

| Working voltage | 380V/50Hz |

| Working environment temperature | -20℃~+40℃ |

| Power | 22KW three-phase asynchronous motor |

| Design output | 20-30 T/H |

| Equipment weight | 1950kg |

Slag processing: crushing all kinds of industrial slag to improve the resource recovery rate.

Metal Recycling: Crushing scrap metal to facilitate subsequent sorting and smelting.

Solid waste treatment: processing of municipal garbage, industrial solid waste, etc.

Building materials production: crushing construction waste to produce recycled aggregates.

Leading technology: continuous innovation, solving industry pain points.

Durable and reliable: made of high quality materials, long equipment life and low maintenance cost.

Environmental protection and high efficiency: sealed design, low noise, no water leakage, no odor, in line with environmental requirements.

Flexible customization: personalized solutions can be provided according to customer needs.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.