【24-Hour Free Consultation & Quote】

WeChat/WhatsApp: +86 199 1475 4015

Submit your inquiry and a dedicated engineer will contact you immediately.

{{ variable.name }}

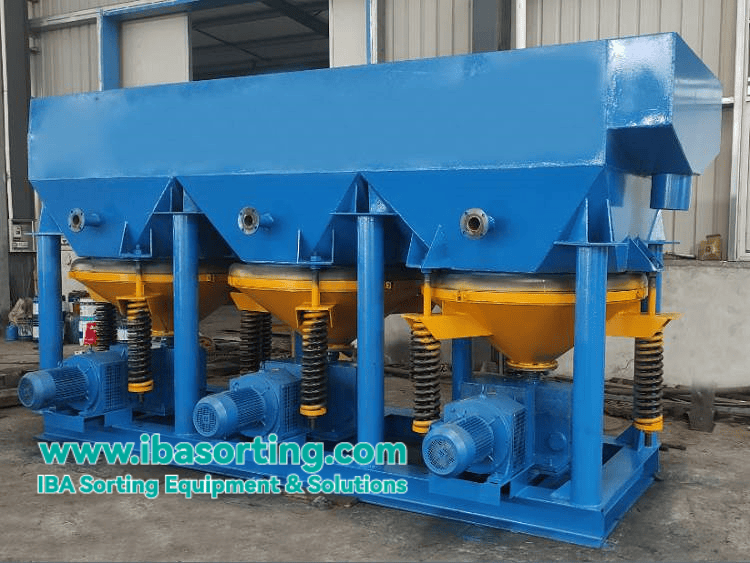

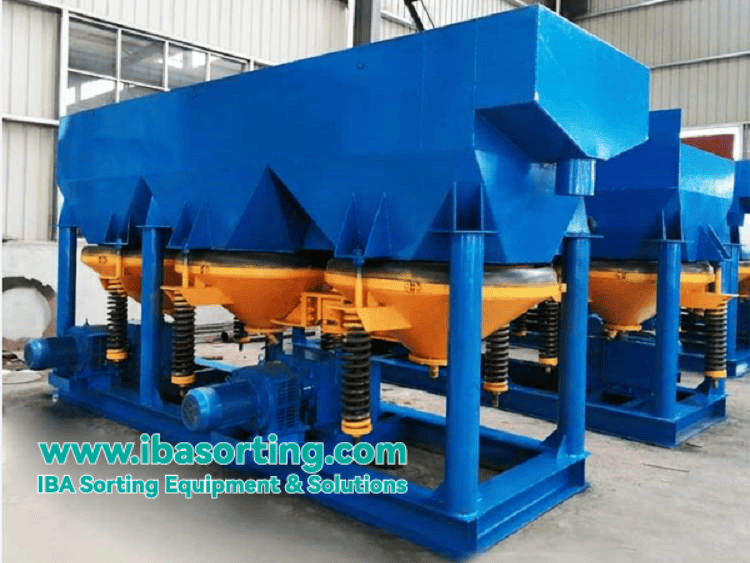

Sawtooth wave jigger is a high-performance gravity concentrator designed with advanced drive technology and unique pulsation curve. It realizes efficient stratification and sorting of mineral particles by simulating the optimized hydrodynamic process, and has significant features such as large processing capacity, high recovery rate, energy saving and environmental protection, and strong adaptability, etc. It is an ideal upgraded alternative to the traditional sinusoidal wave jigger.

The equipment is driven by electromagnetic speed-regulating motor, which produces a unique sawtooth jigging pulsation curve:

Rising water flow is fast: quickly lift the bed to make it fully loose.

Slow descending water flow: provide sufficient time for heavy mineral particles to settle effectively.

This "fast up and slow down" water flow characteristic greatly optimizes the looseness of the bed and stratification efficiency, thus significantly improving the recovery rate of heavy minerals.

| Advantage Category | Specific performance |

|---|---|

| 🔄 Comprehensive improvement of mineral processing indexes | Compared with the traditional jigger, the mineral recovery rate is significantly improved: - Tin (Sn) recovery ↑ 3.01% - Tungsten (W) recovery ↑ 5.5%. - Lead (Pb) Recovery ↑ 1.63% - Zinc (Zn) Recovery ↑ 2.04% - Lead (Pb) Recovery ↑ 1.63% - Tungsten (W) Recovery ↑ 5.5% |

| 💧 Significant reduction in operating costs | Adopting on-screen/under-screen composite discharge method to reduce the amount of make-up water, saving water up to 30%-40%, with low comprehensive beneficiation cost. |

| 📦 Compact structure saves space | The compact design of the equipment reduces the floor space by one-third compared with the traditional equipment, which is easy to install and plan the layout. |

| ⚙ Intelligent operation and flexible adjustment | Adjustable stroke, stepless speed regulation of the stroke, through the electromagnetic speed motor can easily match the process requirements of different ore types and particle sizes. |

| 🛠 Stable operation and easy maintenance | Simple mechanical structure, low failure rate, long service life, installation, operation and daily maintenance are very convenient. |

Precious metals: alluvial gold, silver ore

Non-ferrous metals: tin ore, tungsten ore, lead-zinc ore, antimony ore

Ferrous metals: manganese ore, iron ore, ilmenite ore

Non-metallic minerals: barite, diamond, coal, etc.

Especially good at processing large particle minerals, the maximum feed size of up to 30mm, in barite, manganese ore, iron ore and other mineral processing operations, especially outstanding performance.

Authoritative technology, leading indicators: domestic advanced technology, proven mineral processing efficiency is better than traditional equipment.

Energy saving and consumption reduction, significant benefits: significant savings in water and electricity resources, directly reduce your long-term operating costs.

Multi-purpose, strong adaptability: one equipment can deal with a variety of minerals, wide range of particle size adaptation, high investment value.

Intelligent control, optimized effect: Flexible adjustment of the stroke, ensuring the best sorting effect for different ores.

Sturdy and Reliable, Hassle-free and Durable: Simplified design brings higher stability and lower maintenance requirements.

Sawtooth wave jigger has become one of the core equipments in the field of modern gravity beneficiation with its excellent sorting efficiency, remarkable energy-saving characteristics and wide adaptability, which is a wise choice for you to improve beneficiation indexes and reduce production costs.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.