Incineration Bottom Ash Sorting Solution: Efficiently Recovering Resources, Turning Waste into Treasure, and Helpingthe SlagCircular Economy

Background

With the accelerating process of urbanization, incineration of domestic waste for power generation has become the mainstream treatment method. However, the bottom ash slag produced after incineration is still rich in a large number of recyclable metal resources, such as iron, copper, aluminum, stainless steel, and even trace precious metals. If directly landfill, not only lead to waste of resources, but also cause environmental pollution.

For this reason, we have launched a one-stop incineration bottom ash sorting solution, through a variety of physical sorting methods, efficient extraction of various types of valuable metals, and make the remaining waste residue into building materials, to truly realize the "waste incineration end of the resource," to help the green cycle of development.

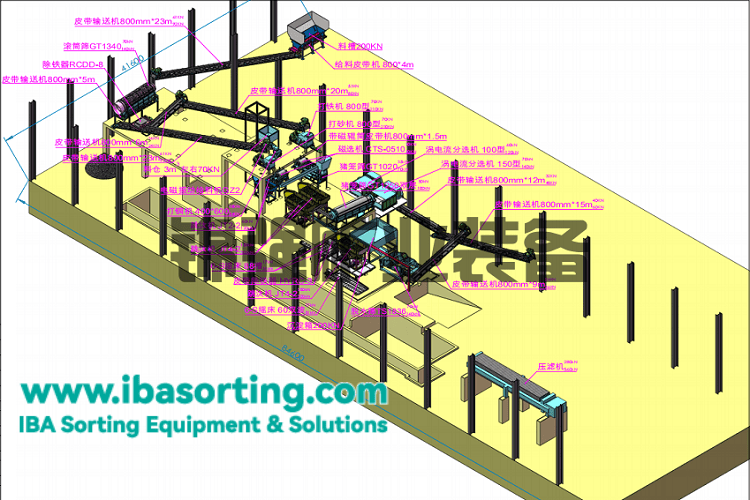

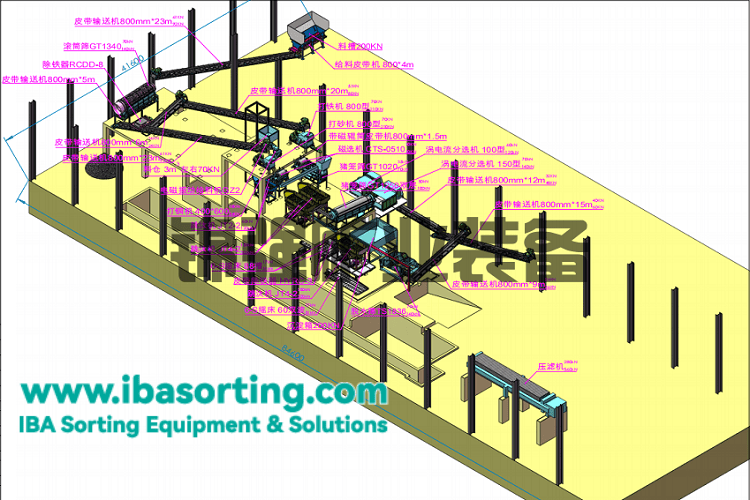

Incineration bottom ash slag sorting process flow

-

Pre-processing: The incineration bottom ash is sent into the hopper by forklift, and enters into the drum screen for preliminary screening through the conveyor belt.

-

Crushing process: large incineration bottom ash into the crusher, crushing to a uniform particle size, to facilitate subsequent sorting.

-

Magnetic separation: the use of permanent magnetic separator to efficiently extract ferrous magnetic metals.

-

Jigging separation: Separate heavy minerals by using sawtooth wave jigger, saving water and high efficiency.

-

Shaking table sorting: fine sorting of copper, aluminum and non-ferrous metals such as gold and silver.

-

Eddy current sorting: precise separation of non-magnetic metals such as aluminum, copper, zinc, etc.

-

Dewatering filter press: slag-water mixture through the dewatering screen and filter press to realize slag-water separation and reuse.

-

Finished product treatment: tailings are piled up and drained for transportation, and used for brick making or building materials production.

Incineration bottom ash slagsorting system and core equipment

| System category |

Core equipment configuration |

| Feeding system |

Plate feeder, vibrating feeder |

| Crushing System |

Slag Crusher, Iron Beater, Copper Beater |

| Screening System |

Tumbler Screen, Vibrating Screen, Dewatering Screen |

| Sorting System |

Permanent Magnetic Separator, Eddy Current Separator, Jigger, Shaker, Stainless Steel Separator |

| Conveying System |

Belt conveyor, screw conveyor |

| Slag water treatment system |

Sedimentation tank, filter press, circulating water pumps |

Incineration bottom ash slag sorting can be recycled resource types

-

✅ Ferrous metal

-

✅ Copper (brass, copper)

-

✅ Aluminum and alloys

-

✅ Stainless steel

-

✅ Copper sand, zinc and other non-ferrous metals

-

✅ Trace gold, silver and other precious metals

-

✅ Finished slag (in line with building materials aggregate standards)

Incineration bottom ash slag sorting program advantages and features

-

High-efficiency sorting capacity: multi-stage crushing combined with intelligent sorting, industry-leading metal recovery rate;

-

Energy saving and environmental protection: recycled water system design, the whole physical sorting, no chemical pollution;

-

Rapid return: low investment cost, 10-18 months to payback, metal earnings continue to be stable;

-

Intelligent control: high degree of automation, easy operation, low labor cost;

-

Flexible customization: support 200-2000 tons per day processing scale, tailor-made incineration bottom ash slag sorting solutions;

-

High resource utilization rate: the tailing slag meets GB/T25032-2010 building materials standards, and can be used for making bricks and road base materials.

Incineration bottom ash project case show

We have provided complete incineration bottom ash slag sorting solutions for many domestic and overseas enterprises, including:

-

1000 tons/day project for a state-owned enterprise in Jiangsu, China

-

1200 tons/day project for a listed company

-

500 tons/day project for a professional slag operator

-

600 tpd for a private enterprise in China

-

1000 tpd project for a large enterprise in Vietnam

We provide full-process service support from design, manufacturing to installation and commissioning.

Customization and Service Support

We promise to provide you:

-

Tailor-made: according to the treatment capacity, site and budget, we provide personalized sorting solutions;

-

Process design: covering process design, site planning and drawing issuance;

-

Equipment selection: flexible combination of modular equipment to meet different scales and needs;

-

Full service: one-stop support from project design, manufacturing, installation guidance, commissioning training to after-sales;

-

Technical response: 24 hours online, remote diagnosis and on-site service combination, to ensure continuous and stable operation.

We provide 10-100 tons per hour incineration bottom ash sorting production line with a full set of equipment and overall solutions, is committed to the mature sorting process and intelligent equipment, to help waste power plants to achieve efficient recovery of metals and resource recycling.

If you need to know more about incineration bottom ash sorting solution details or get a quote, please feel free to contact us!