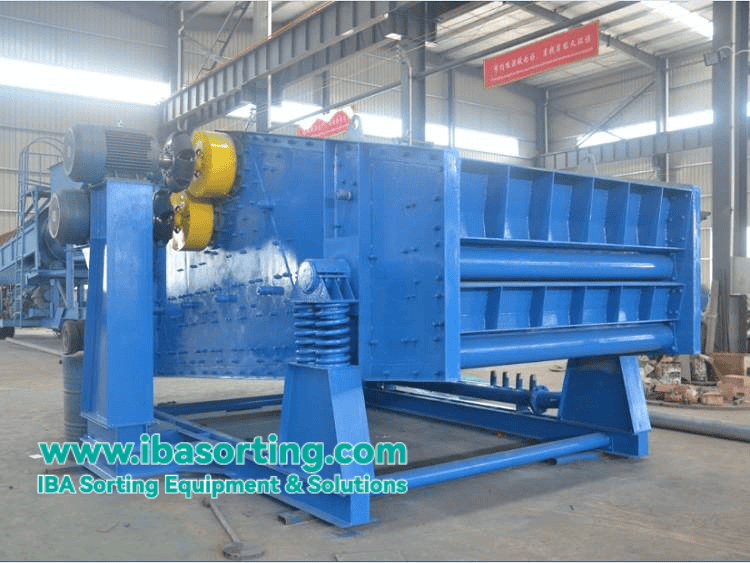

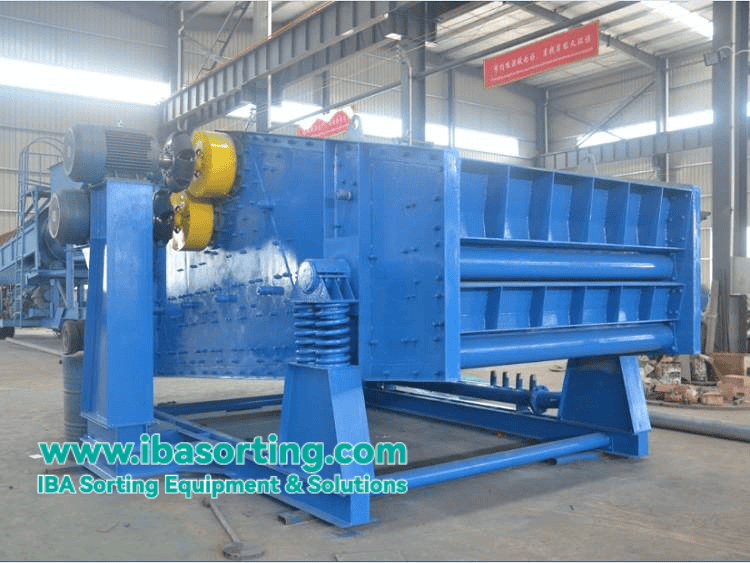

High frequency vibrating screen for slag treatment

High moisture content slag screening expert - key equipment for building materials aggregate preparation

This product is a high-performance vibrating screen designed for waste incineration slag resource processing line, the core solution to the slag crushing due to the extremely high water content caused by the screening efficiency is low, easy to damage the skeleton, water content out of control and other industry pain points. Through all-round innovation and transformation of material, structure and process, this equipment ensures that it can still stably and efficiently complete screening, dewatering and grading operations under adverse working conditions, and is the key equipment necessary for preparing high-quality building materials aggregates.

Core advantages

1. Extraordinary durability, goodbye to "internal injuries".

-

According to the characteristics of slag material, structural strengthening and anti-fatigue design are carried out on key parts such as screen box skeleton and side plate, which can completely solve the problem of cracking of steel structure caused by high-frequency vibration, and significantly prolong the service life of the equipment.

-

High-quality material: the key parts adopt high-strength wear-resistant steel and anticorrosion treatment, adapt to the humid environment, and the durability is far more than that of ordinary vibrating screen.

2. Precise water content control

-

High-efficiency dewatering design: Reasonable screen configuration combined with vibration parameters can effectively separate water and ensure that the moisture content of the screened material (aggregate) is stable and controllable, which fully meets the harsh requirements of downstream brick making or as building material aggregate.

-

Anti-clogging screen mesh: unique screen mesh fixing and tensioning technology, combined with high-frequency vibration, effectively prevents the wet residue from sticking and clogging the mesh holes, and guarantees continuous and efficient dewatering capacity.

3. Extremely high screening efficiency and capacity.

-

Optimized trajectory: Adopting elliptical vibration trajectory, the material jumps forward on the screen surface with diffusion movement, high screening efficiency and large processing capacity.

-

Innovative feeding design: the feeding port is equipped with side rubber screen plate, which effectively utilizes the internal space, prevents the material from splashing and losing, and improves the initial screening efficiency and overall processing capacity.

4. Ultimate maintenance convenience

-

Quick screen change structure: the original screen compression device, no tools, 3-5 minutes to complete the screen replacement, greatly reducing downtime.

-

Strong versatility: support the installation of a variety of screen materials ( nylon, special dragon, PP mesh, etc.), to meet a variety of process requirements from coarse screening classification to fine filtration.

-

Modularized design: simple structure, tight sealing, fewer daily maintenance points, easy operation and low noise.

Working Principle

The equipment is excited by the vibration motor to generate vibration force, so that the screen box drives the screen for high-frequency, small-amplitude elliptical movement. Slag material on the screen surface is thrown up, forward jumping movement; smaller than the aperture of the screen particles and water through the screen mesh to become under the screen, while the specifications of the qualified aggregates continue to move forward along the screen surface and discharged from the discharge port, so as to achieve the purpose of screening, dewatering, grading.

Technical characteristics

-

Screen type: circular vibrating screen / elliptic vibrating screen

-

Driving mode: vibration motor excitation

-

Core function: screening, dewatering, grading

-

Screen configuration: can be customized layer (1-3 layers) and screen hole size

-

Screen material: polyurethane, manganese steel, stainless steel, composite mesh and other wear-resistant and anti-clogging materials can be selected.

-

Sealing: fully closed structure, dustproof and anti-splash, good environmental protection.

-

Application section: It is mainly used in the key screening and dewatering section after slag crushing and before aggregate finished product.

Why choose our slag special vibrating screen?

-

Tailor-made: We deeply understand the characteristics of slag material (high moisture, high wear, complex composition), the equipment is specially designed for this, rather than a simple application of general equipment.

-

Stable and Reliable: Solve the two core pain points of "internal injuries" and "uncontrolled moisture content" to ensure the continuous and stable operation of the whole production line.

-

Economic and efficient: High screening efficiency and low failure rate directly improve the quality of finished aggregates and production line output, creating higher economic benefits for you.

-

Service support: Provide a full range of technical support from screen selection recommendations to equipment maintenance.