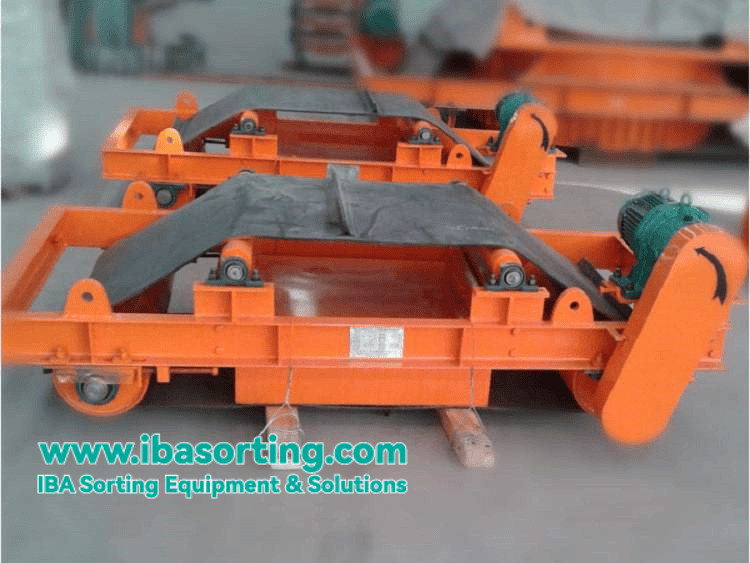

Product Overview

Electromagnetic iron remover is a kind of professional equipment that utilizes the powerful magnetic field attraction to efficiently recover the ferromagnetic impurities in the materials, specially designed for slag processing, can effectively remove the iron parts mixed in the non-magnetic materials, protect the safety of downstream crusher, mill and other equipments, and prevent the large-size iron parts from scratching the conveyor belt, and at the same time, it is vital to enhance the quality of environmentally friendly building materials products, and it can avoid the problem of the surface spotting due to the ferrous impurities. It can avoid the problem of surface spots caused by iron impurities, and protect the beauty and grade of the products.

Core working principle

When the equipment is connected to the power supply, the excitation coil generates a high-intensity magnetic field. When the bulk material on the conveyor belt passes under the iron remover, the ferromagnetic material mixed in it is instantly sucked up. The adsorbed iron parts are thrown out by the continuously running iron unloading belt, and fall into the designated collection device due to gravity and inertia after getting out of the range of magnetic field, thus realizing the automatic and continuous removal of iron impurities.

Equipment structure composition

-

Iron remover body: adopts self-cooling fully closed structure casted with special resin for electrician, with large magnetic penetration depth, strong suction, good heat dissipation performance, strong insulation, and adaptable to harsh environments.

-

Iron unloading mechanism: It contains frame, driving motor, reducer, master/slave roller and iron unloading belt with scraper to realize automatic iron unloading and continuous operation.

-

Magnetic system design: adopting wrapped open magnetic system, effectively avoiding material wrapping or blocking, ensuring the handling capacity.

Technical features and advantages

| Characteristic category |

Detailed description |

| ✅ Efficient and powerful iron removal |

Generate powerful magnetic field, strong suction, can effectively remove the deep buried ferromagnetic impurities, high iron removal efficiency. |

| ✅ Safeguard production safety |

Prevent large and long iron pieces from entering the crusher, grinder and other subsequent equipment, avoid equipment damage and conveyor belt cracking accidents, protect the production line safety. |

| ✅ Enhance product quality |

Effectively removes iron from slag and other materials, avoiding surface discoloration of environmentally friendly building materials caused by iron pollution, significantly improving product purity and appearance grade. |

| ✅ Powerful processing capacity |

The design of open magnetic system makes the material not wrapped up and clogged, and the processing capacity of a single machine can reach more than 120 tons/hour of raw ore, and multiple machines can be connected in parallel to further increase the output significantly. |

| ✅ Stable and reliable operation |

Totally enclosed resin casting structure, dustproof, moistureproof, corrosion-resistant, good insulation performance, adapt to harsh working conditions, low failure rate, long service life. |

| ✅ Automatic continuous operation |

The iron unloading mechanism operates automatically, which can realize continuous iron suction and unloading under unattended operation, greatly saving labor cost and improving production efficiency. |

Typical application scenes

-

Slag treatment and resourceization: recover iron resources from smelting slag and purify the slag for environmental protection building materials production.

-

Solid waste recycling and processing: separating iron materials in garbage crushing lines and resource recycling plants.

-

Mining and Aggregate Industry: Protect crushing equipment and enhance the purity of stone and aggregate products.

-

Coal and power industry: Remove iron from raw coal and protect powder making system equipment.

-

Building materials, ceramics, glass industry: remove iron impurities in raw materials to ensure product quality.

Why choose our electromagnetic iron remover?

-

Professional customization: optimized design specifically for slag characteristics, targeted and effective.

-

Leading technology: the use of high-quality materials and advanced resin casting process, to ensure that the magnetic force is strong and durable and stable.

-

Economical and efficient: large processing capacity, low energy consumption, automated operation, low comprehensive operating costs.

-

Robust: robust structural design, suitable for 24/7 continuous industrial environment operation.