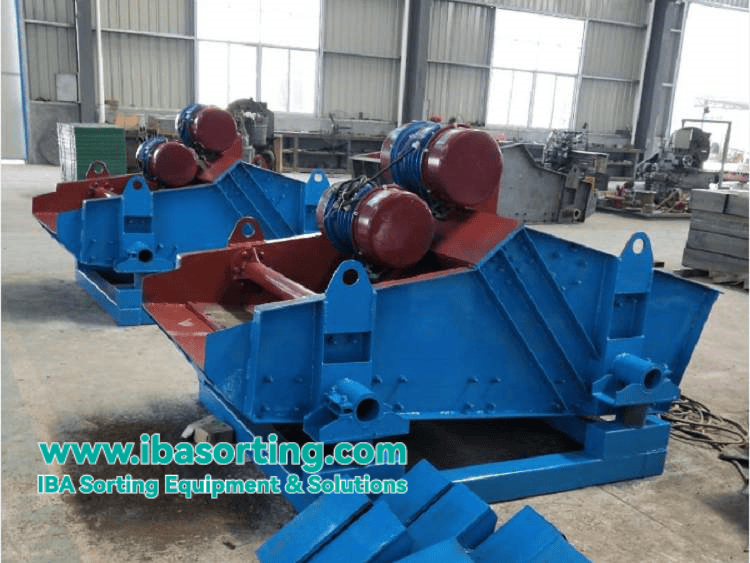

Dewatering screen -- High efficiency dewatering and demediation professional equipment

Product introduction

Dewatering sieve is a professional screening equipment used for material dewatering, desliming and demixing. It adopts mature dual motor self-synchronous vibration technology, stable and reliable operation, high dewatering efficiency, widely used in sand and gravel plant washing sand, coal processing plant coal slurry recovery, tailings dry discharge in mineral processing plant and other operational scenarios, it is the key equipment to realize resource recovery and dry stack processing.

Core structure composition

-

Screen box system: welded with thickened steel plate, the side plate is equipped with reinforcing rib structure, which is sturdy and durable.

-

Vibration device: two vibration motors are fixed by high-strength bolts to generate the excitation force.

-

Support system: high-quality rubber spring damping, effectively reduce the impact load of the equipment on the foundation.

-

Screen component: polyurethane or stainless steel screen plate can be selected to meet the needs of different working conditions.

Technical Characteristics

| Advantage Category |

Detailed description |

| ✅ High efficiency dewatering design |

The screen plate adopts a special inclination arrangement of 5°before and 45°after, which optimizes the material residence time and dewatering path; the screen hole specification can be flexibly selected according to the characteristics of the processed materials, with good dewatering effect. |

| ✅ Stable operation guarantee |

Dual motor self-synchronization technology ensures smooth operation without gear forced synchronization; rubber springs effectively absorb vibration energy, shock absorption effect is remarkable, low noise. |

| ✅ Durable structure design |

Key parts of the reinforced structure design, anti-fatigue; welding process strictly control, to ensure the overall strength and service life. |

| ✅ Easy and economical maintenance |

Simple structural design, the vibration motor is a standard part, easy to replace; the screen plate adopts modular design, local damage can be replaced individually, reducing maintenance costs. |

Technical Parameter Table

| Model |

Size of screen surface (m) |

Motor power (kW×2) |

Capacity (m³/h) |

Weight (kg) |

| TS0720 |

0.7×2.0 |

0.75 |

5-10 |

800 |

| TS0920 |

0.9×2.0 |

1.1 |

10-20 |

1200 |

| TS1020 |

1.0×2.0 |

1.5 |

10-30 |

1600 |

| TS1225 |

1.2×2.5 |

2.2 |

50-80 |

2100 |

| TS1530 |

1.5×3.0 |

3.0 |

100-120 |

3200 |

Note: The above is the standard model parameters, processing capacity varies according to the nature of the material, concentration, particle size and other conditions, support customization.

Main Application Scenario

-

Sand and gravel aggregate industry

-

Application: Used for the final dewatering of washed sand, producing high-quality finished sand with low water content on the surface.

-

Value: Replace the traditional natural sedimentation tank, improve production efficiency and sand quality.

-

Coal Processing

-

Application: Used in coal slurry recovery, coal washing plant media recovery and fine coal dewatering.

-

Value: Effectively reduce product moisture, improve economic efficiency, and realize the closed loop cycle of washing water.

-

Mineral processing production line

-

Application: Used in tailings dry discharge dewatering operation, with thickener, cyclone and other supporting use.

-

Value: Realize the safe storage of tailings, reduce the pressure of tailings storage capacity and environmental risks.

-

Other fields

Selection and Customization Guide

Quality and Service Commitment

-

Quality Assurance: The equipment is tested with no-load test machine before leaving the factory to ensure smooth operation and no abnormality.

-

Warranty of core components: the key components such as vibration motor and screen box are guaranteed for 12 months.

-

Professional technical support: provide the whole process of technical consulting services from selection, installation guidance to maintenance.

-

Customized solutions: according to your specific working conditions and needs, to provide the optimal equipment configuration program.

Note: The technical parameters of this product may be updated without prior notice, subject to the actual order agreement.