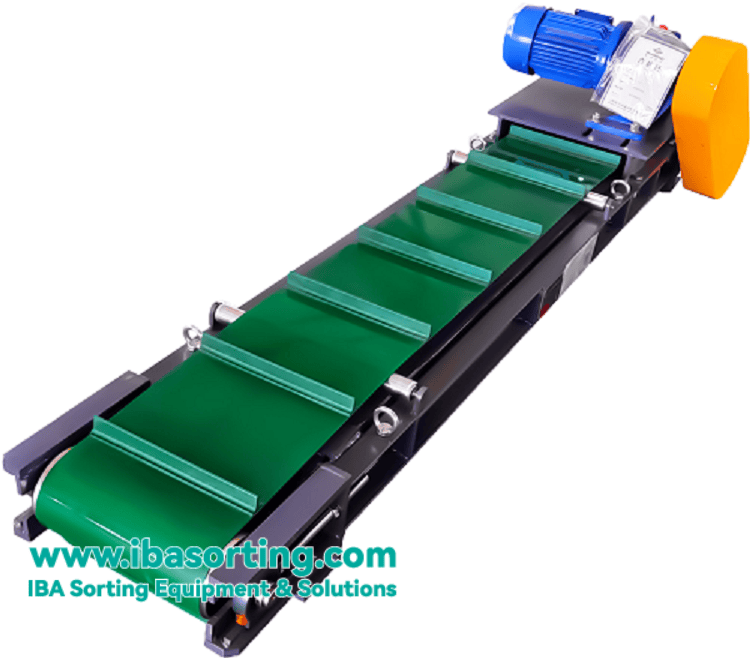

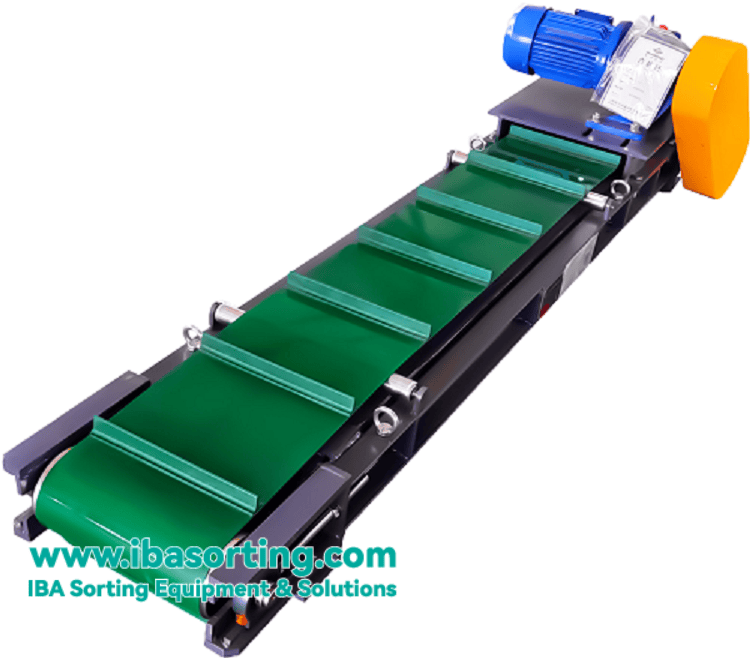

Product Overview

Shaking bed iron remover is a high-efficiency magnetic separation equipment designed for removing ferromagnetic impurities in powdery and fine granular materials. The product adopts unique drum and optimized magnetic circuit design, with stable magnetic field, high iron removal efficiency, reliable operation and other characteristics, widely used in slag, non-ferrous metals, plastics, ceramics, building materials and other industries, material purification, especially suitable for use with 6-S series of shaking table, effectively improve the purity of the sorted materials and product quality.

Core working principle

The material enters into the separating area of the iron remover through the conveyor belt or feeding device, and the drum-shaped magnetic roller generates high intensity magnetic field to adsorb the ferromagnetic impurities in the material. The ferromagnetic material moves with the belt to the weak area of the magnetic field and falls off automatically, while the non-magnetic material passes through normally, thus realizing continuous and efficient automatic iron removal.

Technical Features and Advantages

| Characteristic Category |

Detailed description |

| ✅ High efficiency drum-shaped structure |

The roller adopts unique waist drum shape structure design, with automatic belt deflection correction function, effectively prevent deflection, to ensure the long-term stable operation of the equipment. |

| ✅ Strong and stable magnetic circuit |

Unique magnetic circuit design, high magnetic field strength and reasonable gradient distribution, to ensure the stability of the magnetic field and deep iron removal effect. The core magnetic circuit system provides more than ten years quality guarantee. |

| ✅ Compact and reliable machine |

Compact structure, small footprint, easy to install and maintain. Reliable operation, low failure rate, suitable for continuous industrial production environment. |

| ✅ Optimized for fine powder |

Optimized for powdery and fine granular materials, high iron removal efficiency, effective protection of downstream equipment (e.g. shaker) and improved product purity. |

| ✅ Automated operation |

It can realize fully automatic continuous iron removal and unloading without manual intervention, which greatly saves labor cost and improves production efficiency. |

Typical Application Scenarios

-

Resource recycling industry: removing iron impurities from slag and non-ferrous metal scrap.

-

Building materials and ceramics industry: removing ferromagnetic substances from quartz sand, feldspar powder, kaolin and other raw materials to improve product whiteness and grade.

-

Plastics and food industry: Protect the production equipment and ensure the purity of raw materials.

-

Matching sorting equipment: Used together with 6-S series shaking table and other gravity sorting equipment, as a pre-purification unit, to significantly improve sorting efficiency and concentrate quality.

Why choose our shaking table iron remover?

-

Patented design: the belt drum structure effectively solves the problem of belt deflection, more stable operation.

-

Long-term guarantee: the core magnetic circuit system provides ten-year warranty, durable quality.

-

Efficient purification: specially designed for fine powder materials to remove iron, effectively improve product purity.

-

Compact and flexible: compact structure, easy to integrate into the existing production line.